Last updated on

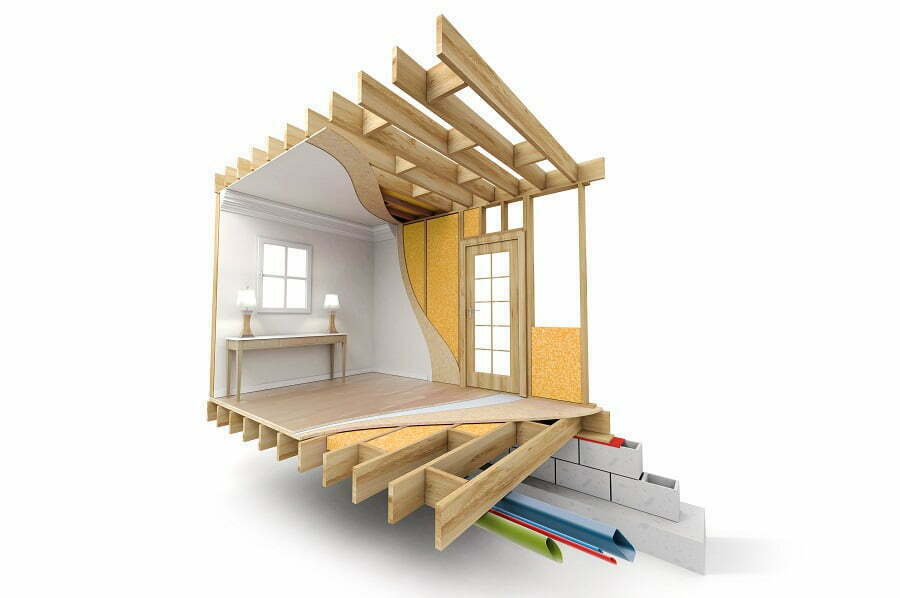

Prefab floor joists make the base of the home’s floor. It is manufactured in the factory like all parts of the prefab.

The prefab floor is typically made of joists, framing, and subfloor structural panels. These components are also made in a factory and delivered to the site to be assembled. Finally, the floors are finished in any type and design of interior flooring.

In this article, we will delve deep into what prefab joists are because it’s the most important part of the prefab’s floor. We’ll discover how the joists are made and what types are available.

Let’s begin!

What Is an Engineered Floor Joist?

Every building structure must have the floor. Once the foundation has been established, the floor has to be installed before the walls can be put up. One of the most common types of floors in North America is the wooden floor. The use of solid timber to make floors has been the industry standard for centuries.

Today, however, more than half of all homes that have wooden floors use engineered floor joists. These are wooden structures designed to overcome the shortcomings of solid timber floors.

Solid timber joists have been known to crown, twist or bow when exposed to humidity and temperature changes. With the use of I-joists, you can be assured of having a strong floor that’s free of the squeaking associated with solid timber defects.

How I-Joist Construction Works

This engineered wood product has been named I-joist because its cross-sectional surface looks like the letter “I.” This type of joist has two main components: 2 flanges and a web.

The flanges make the top and bottom sections of the “I” shape, while the web is the vertical component connecting the two flanges. The web provides shear resistance while the flanges resist bending.

Solid sawn lumber or laminated veneer lumber is used as the flanges, while the webs are made up of OSB or plywood. The result is a joist that can resist bending or shearing and support a lot of weight compared to solid lumber joists of similar weight.

The high strength-to-weight ratio is one of the qualities of I-joists that make them more attractive to engineers and builders. They are much cheaper than solid lumber makes them more attractive to both homeowners and builders.

I-joists can be used both on the floor and the roof and wall studs, among other applications. Many homes have roof rafters, roof joists, and floor joists made up of I-joists.

Common Depths

I-joists come in a variety of sizes depending on the application. The depth of an I-joist can range from 9.25 inches up to 24 inches. However, the 9″, 14″, and 16″ depths are the most common. On the other hand, the length can be as long as 24 feet. However, the most common length of I-joists is 12 to 13 feet. The flange width can also range from 1.5 inches up to 3 inches. A competent installer should be hired to properly size and install the prefab floor joist.

Engineered Wood Floor Systems

Traditional wood floors use solid lumber measuring 2″ by 10″ or 2″ by 12″. However, engineers have discovered that there is a lot of wastage in using solid timber components. By replacing some of these solid timber with engineered products, such as I-joists, engineers can greatly reduce the cost of wood floor construction and improve performance at the same time.

After all, engineered floor systems use 33% less timber because solid timber is only used where necessary. Engineered floor systems offer greater strength and come with fewer defects because I-joists do not bend, split, bow, crown, or shrink.

I-Joists are not used alone; they are designed to be used with glulam and rim boards. The latter are solid timber sections that form the structural perimeter of the engineered wood floor system.

Rim boards come in the same depths as I-joists. Glulam is short for glued laminated timber beams. These are long timber sections that hold the I-joist pieces in place.

Types of Prefab Joists

Three main types of prefab joists are commonly used in engineered floor systems. These are wood I-joists, open-web trusses, and the hybrid type.

- I-Joists are the most widely used due to their affordability and ease of installation. They can also be easily cut to the right length onsite without seeking the approval of an engineer. The most common type of I-joists come with dimension lumber on the bottom and top flanges and an OSB web. The main shortcoming of I-joists is that running electrical, plumbing and HVAC systems through the sections is challenging.

- Open Web Trusses have a longer span than I-Joists (over 24 feet). They are best suited for complex and rugged construction. This system makes use of metal connectors to join the different sections in the engineered floor system. The main advantage of using open web trusses is that you can easily run any type of HVAC, electrical and plumbing system through the trusses. This is a characteristic that can save installers a lot of time and money.

- The Hybrid type seeks to address the shortcomings of both I-joists and open web trusses. Instead of employing metal connectors to connect different sections, the hybrid type uses waterproof heat-treated adhesive and finger joinery to hold everything in place. Another major advantage of the hybrid type is that it can easily be cut to size onsite without the approval of the engineer, unlike the open truss system.

Pros and Cons

As seen above, both the open truss and I-joist systems have advantages and disadvantages, while the hybrid type seeks to overcome those challenges. While I-joists can be cut to size on-site without the engineer’s approval, they usually come in shorter spans.

It can also be incredibly challenging to run electrical, plumbing, and HVAC systems through I-joist flooring systems.

With the open truss system, you get longer spans. It is also much easier to run electrical, plumbing, and HVAC systems through. However, the sharp metal connectors used to connect different sections can cause damage to HVAC, plumbing, and electrical systems.

Cost

Using joists to make wall studs, roof rafters, roof joists, and floor joists is a more cost-effective option than using solid timber. It is estimated that using these engineered systems can reduce timber consumption by a third.

As a result, you can save a considerable amount of money if you choose to use I-joists and open truss systems instead of using solid timber when building the floor and roof of your home.

FAQ

Yes! Joists require skilled labor and expensive machinery to produce them. In addition, they are difficult to transport and store. On the other hand, engineered floor joists can be produced at low costs and transported easily.

Engineered floor joists are made from high-quality plywood and solid lumber materials. Therefore, they can last for decades.

TJI joists look like steel beams but are made of engineered wood (laminated veneer lumber or solid lumber).

Table of Contents

![How Much Does an ADU Cost? [Solved]](https://buildgreennh.com/wp-content/uploads/2022/08/ADU-Tax-Deductions-and-Benefits.jpg)

![How to Build an ADU? [Step-by-Step]](https://buildgreennh.com/wp-content/uploads/2022/08/Why-Are-You-Building-an-ADU.jpg)