Last updated on

Imagine a world where buildings rise efficiently, with precision and purpose, harmoniously melding with the environment. This isn’t a distant dream anymore. Today, it’s a tangible reality being shaped by groundbreaking tools and methods in green modular construction. In this realm, efficiency and sustainability aren’t mere buzzwords but the core pillars upon which every structure stands.

In this article, we’ll unravel how cutting-edge tools are redefining efficiency and sustainability in construction, one module at a time. Read on!

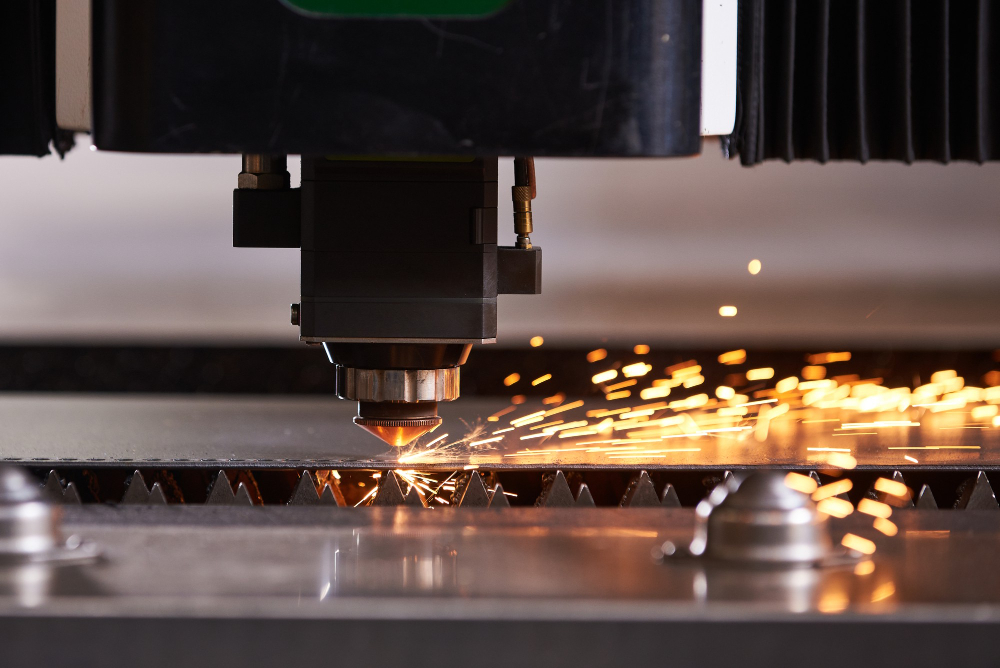

Plasma Cutting Machines

Plasma cutting machines, known for their ability to cut through various metals with remarkable precision and speed, play a crucial role in ensuring the components of modular buildings fit together seamlessly. This precision is vital in modular construction, where the integrity of the structure depends on the exactness of each component.

By ensuring accuracy, plasma cutters minimize material waste—a key aspect of sustainable building practices. Moreover, their ability to handle recycled metals aligns perfectly with the ethos of green construction, which emphasizes the reuse of materials to reduce environmental impact.

In addition to their role in material efficiency, modern plasma cutting machines are more energy-efficient, reducing the overall energy footprint of the construction process.

Furthermore, the integration of advanced technologies like CNC (computer numerical control) into plasma cutting machines allows for automated, precise cuts that reduce labor costs and time, contributing to overall efficiency.

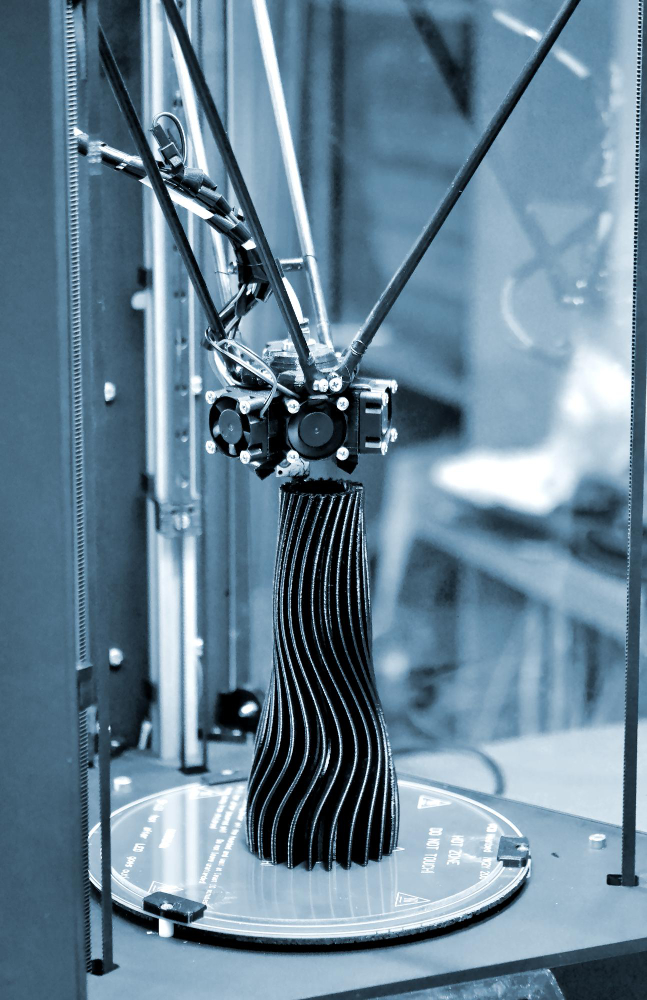

3D Printing Technology

This technology allows for the production of complex architectural components with remarkable precision and flexibility. To add, its ability to print using a variety of materials, including eco-friendly and recycled materials, makes it a cornerstone in sustainable building practices.

By precisely printing components as needed, 3D printing significantly reduces material waste compared to traditional construction methods, lowering the carbon footprint associated with the transportation and processing of building materials.

Also, the tailored production process of 3D printing aligns seamlessly with the principles of modular construction, where each module or component can be custom-made to fit into a predetermined design, ensuring minimal on-site adjustments and waste.

Furthermore, 3D printing in green modular construction heralds a new era of design possibilities and efficiency. With this technology, architects and builders are no longer constrained by the limitations of traditional construction methods, enabling the creation of more organic, efficient, and innovative designs that were previously challenging or impossible to achieve.

The speed of 3D printing also plays a pivotal role in enhancing efficiency. So, projects can be completed faster, reducing labor costs and the environmental impact of prolonged construction activities.

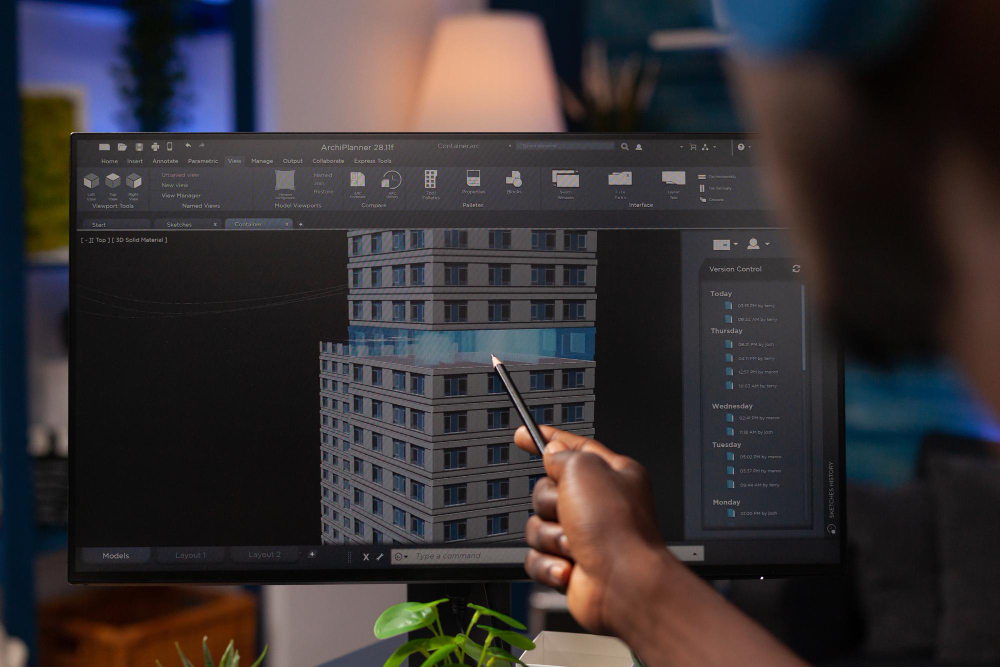

BIM (Building Information Modeling)

BIM creates a comprehensive digital representation of a building’s physical and functional attributes. It enables architects, engineers, and contractors to visualize the entire building in a virtual environment before any physical work begins. This foresight allows for meticulous planning and coordination, ensuring that each module or component is designed for optimal efficiency and sustainability.

The ability to simulate and analyze various aspects of the building, such as energy performance and material sustainability, before actual construction makes BIM an invaluable asset in achieving green building goals. It helps in identifying potential issues early in the design phase, reducing the risk of costly modifications later on and significantly reducing waste.

Moreover, BIM’s role in enhancing communication and collaboration across different teams involved in a modular construction project can’t be overstated. By providing a shared, up-to-date model of the project, this tool facilitates better decision-making and coordination among all stakeholders, streamlining the construction process. This integration is crucial in modular construction, where different modules are often constructed simultaneously at different locations.

Solar-powered Equipment

The integration of solar power in construction sites is a leap forward in reducing the carbon footprint of the building process. Moreover, the adaptability of tools like solar-powered cranes and saws to various settings, including remote and off-grid locations, enhances its utility in modular construction projects, ensuring that sustainability goals are met irrespective of the geographical constraints.

Furthermore, the cost savings associated with reduced fuel consumption and lower maintenance requirements of solar-powered equipment further add to their appeal.

Additionally, the innovation in solar technology continues to advance, making these tools more efficient and reliable. As solar panels become more efficient and battery storage capabilities improve, the range and functionality of solar-powered construction equipment expand, opening new avenues for sustainable building practices.

Smart Sensors and Internet of Things (IoT)

In the modular construction process, smart sensors can be used to monitor various aspects of the environment and the building components themselves. For instance, they can track humidity, temperature, and structural integrity, ensuring that the modules are constructed under optimal conditions, thereby enhancing quality and durability. This real-time data collection and analysis leads to more informed decision-making, reducing the risk of errors and material waste.

Meanwhile, IoT devices enable seamless communication between different components of a modular construction project. From the manufacturing of modules in a factory to their assembly on-site, IoT ensures that each stage of construction is optimized for efficiency and sustainability.

This interconnectedness not only streamlines the construction process but also enables a more dynamic and responsive approach to building, where adjustments can be made swiftly to accommodate any changes or challenges.

Beyond the construction phase, smart sensors and IoT play a significant role in the life cycle management of green modular buildings. These technologies can be embedded within the structures to continuously monitor energy usage, detect maintenance needs, and even regulate building systems to optimize energy efficiency.

The Takeaway

These advancements aren’t only enhancing efficiency and precision in the building process but are also pivotal in driving sustainability, reducing environmental impact, and promoting energy efficiency. As these technologies continue to evolve and integrate, they pave the way for a more sustainable future in construction, demonstrating that efficiency and environmental responsibility can go hand in hand.

Related reading:

Table of Contents