Last updated on

Denim insulation is the new popular type of environmentally-friendly material. Let’s see what it’s all about and compare it to other popular materials in layman’s terms.

The idea of recycling old denim that otherwise fills up landfills is a neat idea that helps the environment too. If you can make use of wasted jeans for something as useful as insulation, you can solve two problems at the same time.

But is denim a good material for insulation? How does it compare to other popular solutions like fiberglass, cellulose, or plastics? Is it worth investing in? These are all important questions that will help you decide if you want to deal with denim at all.

Insulation Ratings

Before we start talking about the various types and materials for insulation, we need to get the important terms right. The main metric you will need to know about the material you will use for insulation anything is the R-value.

In layman’s terms, it’s the material’s ability to stop heat from going out of or into the house. Thus, for any wall, roof, floor, or anther barrier you will need to know the recommended R-value if the material is going to be enough to insulate your home.

How do you know the R-value you need?

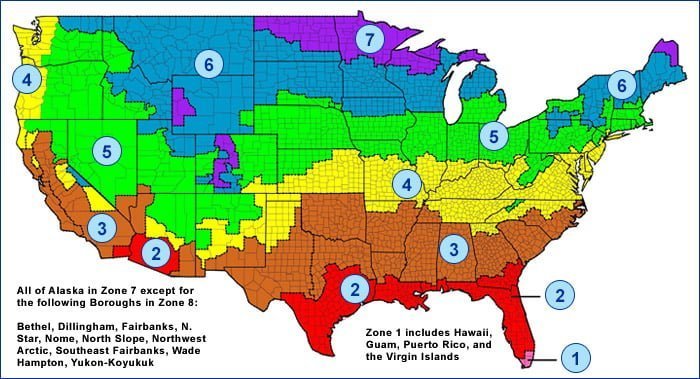

Energy Star recommends the following insulation ratings in the US, based on the climate per state:

The map is divided into climate zones, and each of them has different R-values. It’s important to note that these values also depend on the type of barrier, heating system, and house building construction itself. So for your exact recommendation, you will need to get in touch with an insulation specialist.

This table gives you the approximate values which will help you decide on the material needed to insulate your home properly.

Blue Jeans Insulation

To any homeowner who is environmentally-aware, and who looks to minimize their footprint by using renewable and efficient technologies, denim is an attractive option. Just think about how many blue jeans you’ve worn down and threw away (or reused) in your lifetime. How much of insulation they could’ve made? On this same note, denim insulator manufacturers recycle old jeans to produce an excellent insulator.

It is a little more expensive than the alternatives, but the efficiency and impact on the environment (as well as the sentiment) may be well worth it.

Recycled Denim Insulation

Jeans are recycled into insulation material by programs like Blue Jeans Go Green. This is your way to turn your pile of jeans into insulation for your home. What does this mean?

You cannot turn denim into an insulator yourself but you can mail it to the program so it stays out of the landfill. Let them do their job. At the same time, you can choose denim insulation to insulate your home (you can even do it as a DIY project).

Denim Roll

Denim insulation is normally sold in rolls of batting. These rolls allow you to plan and install insulation between house studs and cover the area completely. The rolls are usually punctured for easy dividing into needed parts. It is possible to cut denim too.

Ultratouch Denim Insulation

The most popular recycled denim insulation product is the Ultratouch Denim batt solution. As a green and efficient insulation material, it costs from $1 per square foot to insulate at R30.

Pros of Ultratouch Denim Batt

- It is not irritant – it’s easy to handle.

- It’s just as efficient as other fiber batt solutions.

- It’s made from recycled denim, which is environmentally-friendly.

Cons of Ultratouch Denim Batt

- It’s more expensive than some of the other recycled insulation materials.

Recycle Jeans

Stocked up on blue jeans and want to get rid of a pile of them (while staying environmentally-friendly)? Here’s how to recycle denim:

- Donate them to a thrift store if they are still usable.

- Upcycle them into a DIY project.

- Bring them to the Blue Jeans Go Green Program where it will be turned into insulation.

- Bring it to any Levi’s Store where it’s accepted for recycling.

- Nudie Jeans Co has a similar program.

- Check your local community for recycling programs.

Recycle Jeans for Cash

Several retailers have programs that reward recycling old jeans. Some popular retailers with such programs are:

- Levi’s

- H&M

- Kiehl’s

- Madewell

- The North Face

- Rag & Bone

- Gap

- Guess

- Bloomingdale’s

- and more…

Formaldehyde in Jeans

Formaldehyde is an organic compound used to preserve clothing, to prevent wrinkles and mildew. Jeans are no exception. The bad part is that this compound is known to cause illness. The good news is that you can get rid of most of it by washing your clothes at higher temperatures.

As denim insulation is concerned, does it comes with formaldehyde that is found in denim products? The answer is no. During the recycling and manufacture process of insulation batts, the compound is eliminated from the fabric.

Denim Insulation vs Fiberglass

One of the most popular insulation materials is fiberglass. It’s efficient and relatively cheap, though it has some serious drawbacks. As denim is an up and coming contender among the best solutions, let’s compare the two.

Price

Fiberglass is generally cheaper at $0.5 per square foot, while Denim starts at $1. That’s the main point at which fiberglass has an advantage.

R-value

This is the main quality of insulation material as it indicates how well it blocks heat from going out of or coming into the house. Fiberglass comes behind denim here. At the thickness of 3.5 inches fiberglass has R-value of 10.9, while denim comes in at 13.

It may not seem like much but when it comes to the amount of the material needed to get the right level of insulation, denim wins back a few points it had lost with pricing.

Noise reduction

Fiberglass gives us the NRC of up to 0.95, meanwhile, denim insulation boasts the coefficient of 1.15. Again, denim gets a few points back.

Fire resistance

Both, fiberglass and denim insulation (which is treated with fire retardant) are fire resistant.

Health concerns

The biggest disadvantage of fiberglass is its inherent danger to human health. The micro shards of glass of which the fiber is made can irritate skin and do damage to the lungs if precaution is not taken. Should insulation get exposed at any point during exploitation, it may cause harm to those who get in contact.

This is not the case with denim. It’s basically recycled cotton which has no negative impact. The most you may need if you’re installing it as a DIY project is a mask against dust.

Environmental impact

Fiberglass isn’t biodegradable (or it takes a long time to degrade in the best case scenario). It is likely to have a negative impact on the environment if not recycled. On the other hand, denim is bio-degradable having an only minimal negative impact on the environment, if not recycled. Better yet, it’s made from recycled materials, to begin with.

Main Takeaway

All things considered, denim insulation provides more value for the money. Unless your immediate budget is your only concern, you will do better with denim in the long run anyway.

Where to Buy Recycled Denim Insulation?

Many hardware stores and online stores now sell denim insulation so it’s readily available. Some of the most popular places include:

- Home Depot

- Amazon

- Lowes

Insulation Prices

The average homeowner spends $1,000 to $2,300 to insulate their home. This is a rough guideline assuming average conditions. However, it will depend greatly on many criteria on a case by case basis.

What are the keys to lowering insulation costs?

- DIY instead of hiring a contractor.

- Use cheap recycled insulation (such as cellulose fiber).

- Improve the efficiency of your house construction (cover air leaks).

Insulation cost per square foot comparison

- Cellulose – from $0.35 per square foot

- Fiberglass – from $0.5 per square foot

- Denim – from $1 per square foot

Cheap Insulation – Recycled Paper

When choosing the material, cost no doubt may become the deciding factor. Indeed, if you can get cheap material, you can use thicker barriers made of it in order to achieve the required insulation (R-value). So what are your options?

We’ll go over the insulation pricing next, but the cheapest option has to be cellulose made from recycled paper. The cost starts at about $0.7 per pound (even less if you make it yourself).

How much do you need of recycled cellulose insulation for your home?

Its R-value starts at about 3.7 per inch thickness, and you can get up to R60 (so that’s about 16 inches). A 19-pound pack can cover roughly 13 square feet area. At R19 it will cover 40 square feet.

Roof Insulation

Roof (or the attic) is the least insulated space of a house by construction, thus it requires insulation material with the highest R-value. Many materials, that are good for walls or floors may not be sufficient enough to insulation roof.

What materials are suitable to insulate the roof?

- Most plastic insulation materials

- Rock wool

- Glass wool

- Cellulose fiber

- Glass fiber

- Cotton

- Denim

- Most natural insulation materials (sheep wool, hemp, cork, etc.)

The type you have to choose depends on the recommended R-value in your area and the thickness of the material you can afford to use.

Best Attic Insulation Material

Attic or roof needs the highest R-value (typically up to R60), thus the most efficient material is best used. Of course, you can insulate attic in a higher thickness of batting or loose-fill to get the needed R-value as well.

Generally speaking, most loose-fill and batting insulation solutions have similar R-value per inch, thus the deciding factors are the price, safety, and environmental footprint. On the other hand, aerogel and polyurethane panels have a significantly higher R-value per inch thus providing a more reasonable option for the roof construction.

Safe Insulation

What insulation is safe? The short answer is the one that uses natural materials or recycled from materials that are not known to cause harm. It should not be harmful during installation nor exploitation.

The following materials can be considered as safe in these regards:

- Denim

- Cotton

- Cellulose

- Wool, hemp, straw, seaweed

NRC Rating

The Noise Reduction Coefficient is a value that indicates how much sound a material absorbs (on a scale of 0 to 1). Which means a material that reflects all sound has an NRC rating of 0, and a material that absorbs all sound has an NRC rating of 1. The rating is not absolute so some materials that have great sound absorption qualities may have the rating slightly higher than 1.

Sound Batt Insulation

Insulation batts of any material have the ability to absorb sound per definition. That means by insulation your home thermally you are blocking most of the sound from the outside too. The only thing to get right is the NPC rating of the material.

So if your house is built in a particularly noisy environment, you should take special measures to use insulation with a high NPC rating. For other cases, regular insulation will hold its worth to reduce noise.

If, on the other hand, you need to block sound in the interior, you can do that with blanket insulation or batts of a high NPC. What are your options?

- The already mentioned insulation batts with high NPC

- Acoustic foam

- Acoustic fabrics

- Acoustic boards

Denim insulation with NPC of 1.15 is a good sound insulator.

Denim insulation soundproofing

What NRC rating does denim insulation have? According to Bonded Logic, the manufacturer of Ultratouch denim insulation, it has an NRC rating of 1.15.

Fire Resistant Insulation

It’s important to note that not all insulation materials are fire-resistant. To be fire-resistant, an insulator needs to be either made from a material that is non-combustible or treated to be resistant.

These are the insulation materials that are fire resistant:

- Denim insulation treated with a boric acid (fire retardant.)

- Aerogel

- Fiberglass

Common insulators that are flammable (if untreated):

- Mineral wool (which specific exceptions)

- Cellulose

- Most natural materials

What is Insulation Made of?

The most common insulation materials by type are the following.

Blanket batts and rolls

- Fiberglass

- Natural materials

- Mineral wool

- Plastic fibers

Concrete block insulation and structural panels

- Foam board (Polystyrene, Polyurethane, Polyisocyanurate)

Loose-fill

- Cellulose

- Fiberglass

- Mineral wool

Sprayed foam

- Phenolic

- Polyurethane

- Polyisocyanurate

Uses of Cellulose

Cellulose is one of the cheapest and efficient insulation materials, but there are more uses which makes this material very versatile:

- Paper products

- Fibers

- Insulation

- Consumables

- Building material

- Biofuel

Cotton Insulation

Recycled cotton is a highly efficient material for insulation. Whether it’s denim of other kids of cotton, the insulator usually has very low thermal conductivity, it’s reusable, bio-degradable, and environmentally- friendly. Think about it as clothing which you use to protect yourself against the weather. Those same qualities of cotton are used as an excellent insulator in homebuilding.

The Pros of Cotton Insulation

- It has a high R-value.

- It’s a non-irritating material that needs no special measures to use.

- It’s friendly to the environment.

The Cons if Cotton Insulation

- It costs more than some other insulation materials (such as fiberglass, or cellulose).

Is Denim Cotton?

When we’re talking about recycled cotton as an insulator, is this the same as to talk about denim? Indeed, denim is made of cotton. In fact, most cotton insulation products recycle denim in their manufacturing.

Non-Fiberglass Insulation

Fiberglass is one of the most popular materials of insulation. It’s efficient and cost-effective. But the biggest drawback it has is that it may be dangerous to health when working with it or being exposed to the fiber with no protection. It’s all due to the nature of it being made of micro glass shards to form the fiber.

Therefore, if it’s a concern, alternatives are required. Here’s what you can use instead of fiberglass:

- Denim insulation

- Cellulose

- Plastics

- Foam

- Natural materials

As we are all about green building, we advocate materials that are recycled and renewable (such as denim, cellulose, and natural materials).

Recycled Insulation

Building a green house requires the use of recycled and renewable materials. Insulation is one of the areas where a lot of recycled and waste materials can be utilized. What are these materials:

- PET bottles

- Denim

- Paper

- Glass

- Natural materials (sheep wool, jute, seaweed, etc.)

Insulation Batting

Insulation batting is one of the most accessible and easily used types of insulation. It comes in the form of rolls which can then be inserted between building studs during construction or renovation.

Here are the most popular types of batt materials:

- Fiberglass

- Denim

- Mineral wool

- Natural materials (like sheep wool, straw, seaweed, etc.)

How Long Does Insulation Last?

Modern insulation can last over 100 years. It is built to last. Indeed, you can safely assume that under normal circumstances with no natural disasters occurred, it will last you a lifetime. That’s not to say that you don’t have to look after possible damages down the road.

Some things can affect how your home insulation’s efficiency. Water leaks, tears, may render parts of it weak leading to thermal leaks. For instance, a tear in a single batt will render the area ineffectively insulated.

Insulating Bathroom Walls

Insulating bathroom walls comes with an extra precaution. You have to take into account the additional humidity that this room typically endures. Thus, all structural decisions have to be made with this in mind.

As a general rule, all non-porous (i.e. loose and spray) materials are better than batting because there’s less space for humidity to accrue or mold to grow. With that said, most highly efficient solutions are water resident and have mold prevention, making them a good choice nonetheless.

How does denim fair in this regard? We know that Ultratouch Denim is treated against mold, thus making it safe for bathroom walls.

How to Make Insulation?

So you’re a DIYer and want to save money by making your own insulation. These are the key points to have in mind if you want to do it.

In general, most types of insulation materials go through a complicated manufacturing process. These processes are very difficult to replicate under home conditions (if possible at all).

However, there’s one kind of material that you can use, and that’s recycled paper turned into cellulose. We’ve already talked about its features.

What you will need:

- A decent hammermill to grind paper into a fine fiber.

- Boric acid as a fire retardant to make cellulose fire-resistant (borax is a cheap alternative).

- Aluminum sulfate as a rodent and insect repellent.

Things to keep in mind:

- You need to make sure paper is properly dried before grinding. Otherwise, you’ll be making a compost rather than cellulose.

- While borax is safe (it’s used in soaps), aluminum sulfate albeit non-toxic is an irritant so you have to safeguard your skin and eyes when using it.

- Aluminum sulfate is corrosive to metals, so if you’re insulating a metal construction, dilute it with regular lime (in half and half proportions).

The price of such homemade insulation (excluding the price of the hammermill tool) is $0.05 per square foot.

How is Insulation Made?

The process of making insulation can be broken down to these main steps:

- The material is gathered (such as recycled denim, paper, natural materials, etc.)

- The material is shredded and ground into fiber

- The fiber is processed with a fire retardant, rodent and insect repellent, mold repellent

- Depending on the type of insulation, batts, blankets, or loose-fill is formed.

How Denim Insulation is Made?

Denim insulation undergoes a very similar process of manufacturing like most insulation batts. Here’s how it works:

- Old denim is collected from recycling.

- Buttons and zippers are removed.

- It is then shredded and ground into bales.

- These bales are then processed to unweave the remaining denim and turn it into a fiber.

- The fiber is treated with boric acid to become fire-resistant and mold-repellent.

- Before the final pressing, it’s combined with other cotton fiber.

- The fiber is pressed into 2-inch batts for the final product.

Temporary Insulation

What do you do when your insulation is broken or when you need to temporarily insulate a construction which is still being built? You can use the following materials:

- Leftover building materials, such as housewrap

- Polystyrene blocks

- Bubblewrap

- Cardboard

The only important point to keep in mind is that such insulation will not meet any standards and only provide some thermal resistance. You should install proper insulation as soon as possible.

FAQ

It’s the insulation material made of recycled jeans. We talk about it in our article extensively.

The NRC rating (Noise Reduction Coefficient) indicates how well a material absorbs sound. Denim insulation has an NRC of 1.15.

Recycled materials are always cheaper, so try your local Habitat for Humanity Restore.

Hardware stores or online. Try Amazon, Home Depot, Lowes, etc.

R13 at 3.5 inch thickness.

Recycled jeans (denim) mixed with other cotton fibers.

Table of Contents