Last updated on

Dive into the world of grain bin sheds, because these innovative and sustainable spaces could transform your landscaping and storage needs.

Embracing sustainability demands a creative spirit, especially when it comes to reimagining unused spaces. Grain bins, staple silhouettes on the farmland, hold enormous potential for shed conversion.

This article aims to shed light on unique grain bin shed ideas, reaching beyond the familiar. While we’ll provide resources for tried-and-true designs, our focus will be on fresh, unexplored concepts that promise to enhance your spaces’ functionality and aesthetic.

So, ready to redefine your grain bin perspective? Let’s delve into this treasure trove of untapped potential.

Eco-friendly Grain Bin Shed Designs

Incorporating eco-friendly elements into a grain bin shed can greatly reduce its environmental footprint while maintaining functionality. Here are key points to consider:

- Use recycled materials: Opt for reclaimed wood, metal, or other materials in the construction to minimize waste.

- Install solar panels: Solar power can provide a renewable energy source to run any electrical needs in the shed.

- Implement rainwater harvesting: Equip your shed with a system to collect and reuse rainwater for irrigation or other operational needs.

- Enhance insulation: Superior insulation can keep the interior temperature regulated, reducing the need for additional heating or cooling.

- Choose green roofing: Green roofs, covered with vegetation, can improve insulation, reduce water runoff, and promote biodiversity.

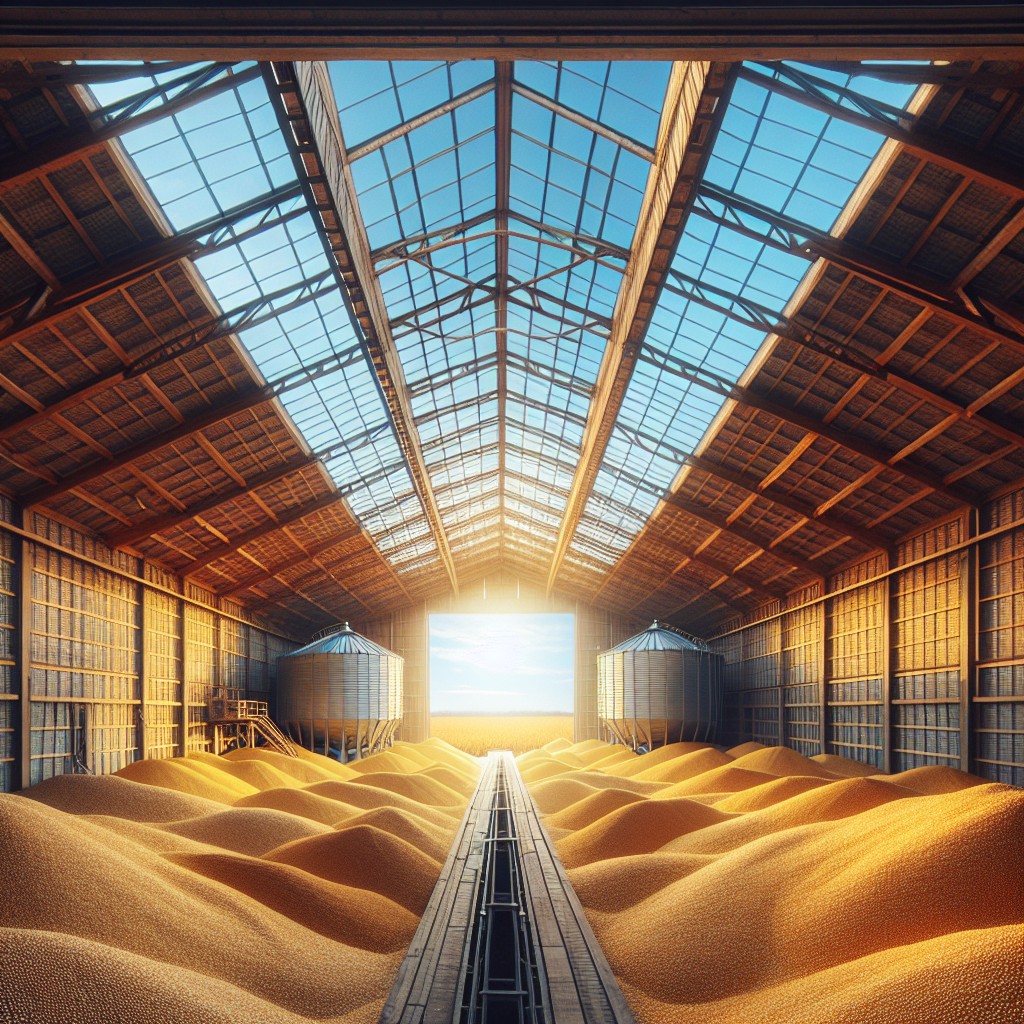

- Include natural lighting: Design the shed with ample windows or skylights to minimize the need for artificial lighting during the day.

- Apply non-toxic finishes: When painting or sealing the shed, select products with low volatile organic compounds (VOCs).

- Integrate smart design: Thoughtful orientation and design can maximize natural ventilation and light, lessening reliance on mechanical systems.

By focusing on these sustainable strategies, your grain bin shed not only becomes more eco-friendly but also potentially more cost-effective in the long run.

Modern Grain Bin Shed Aesthetics

Incorporating sleek lines and minimalist features, modern grain bin sheds blend functionality with style. Large, clear windows enhance natural lighting, creating an inviting interior atmosphere, while the use of durable, eco-friendly materials ensures long-term sustainability.

To complement contemporary farm landscapes, neutral color palettes with bold accent hues are often selected. The exterior may showcase innovative touches like living green walls or architectural cladding, adding to the aesthetic appeal without sacrificing practicality.

Outdoor lighting is designed to be both functional and visually appealing, strategically placed to highlight the shed’s design elements after dark. The integration of smart technology adds a layer of convenience, allowing monitoring and operation from a distance.

Overall, these design principles transform traditional storage into a statement piece that stands out on any modern farm.

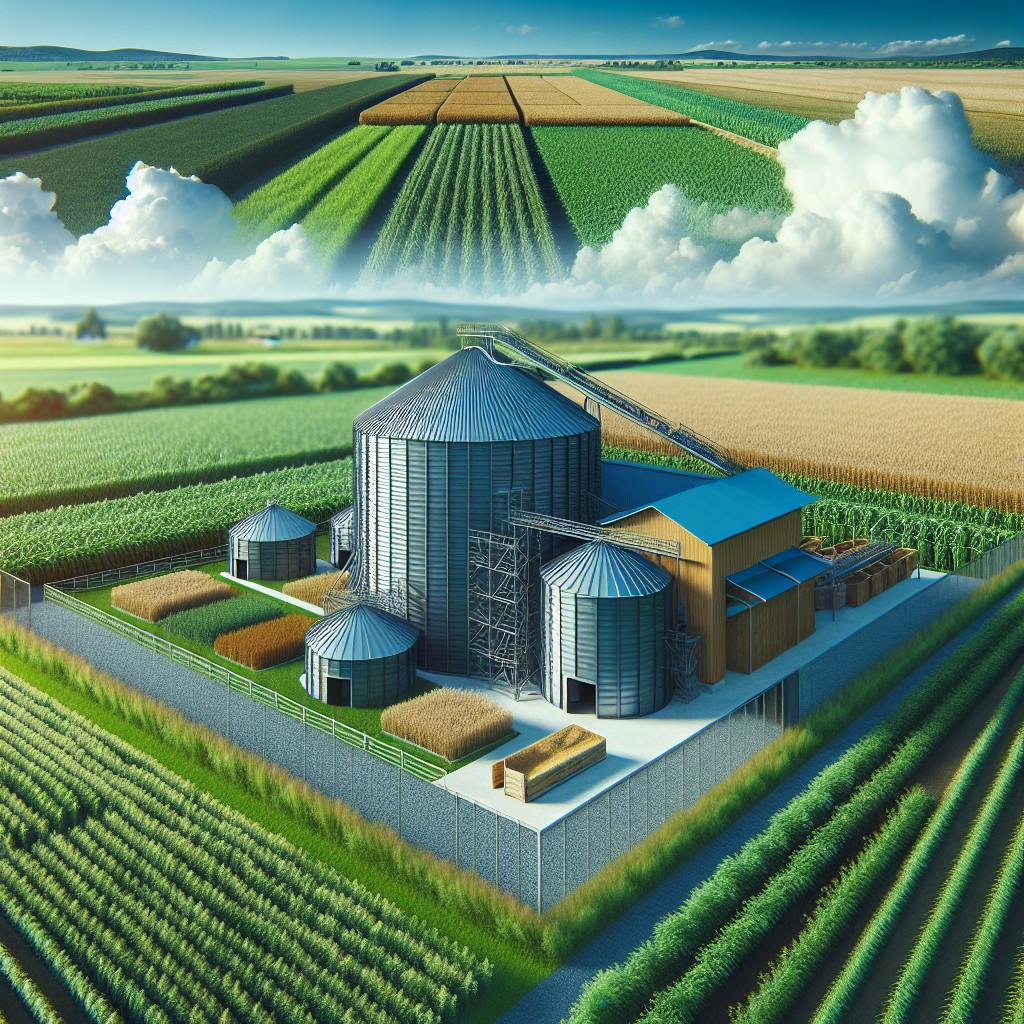

Grain Bin Sheds for Small Farms

Adapting to the limited acreage and budget constraints that often characterize small-scale agriculture, grain bin sheds tailored to petite operations can offer a myriad of benefits. Space efficiency reigns supreme; farmers can utilize compact structures that blend seamlessly with their existing infrastructure. Moreover, these sheds are typically easier to install and can be more cost-effective than their larger counterparts, given their reduced material requirements.

Customization options abound: doors, windows, and interior partitions can be positioned to facilitate daily workflows. Additionally, these sheds can cater to multifunctional use—a space not just for grain storage, but also for housing farm equipment or serving as a workshop. The smaller size also means a lessened environmental footprint, especially when incorporating sustainable materials and practices.

A crucial point for small farm owners to consider is the potential for future expansion. With modular design elements, these sheds can be efficiently scaled up to accommodate growth over time. Ensuring that the design is durable and weather-resistant is equally important, guaranteeing longevity and protecting the stored goods against the elements.

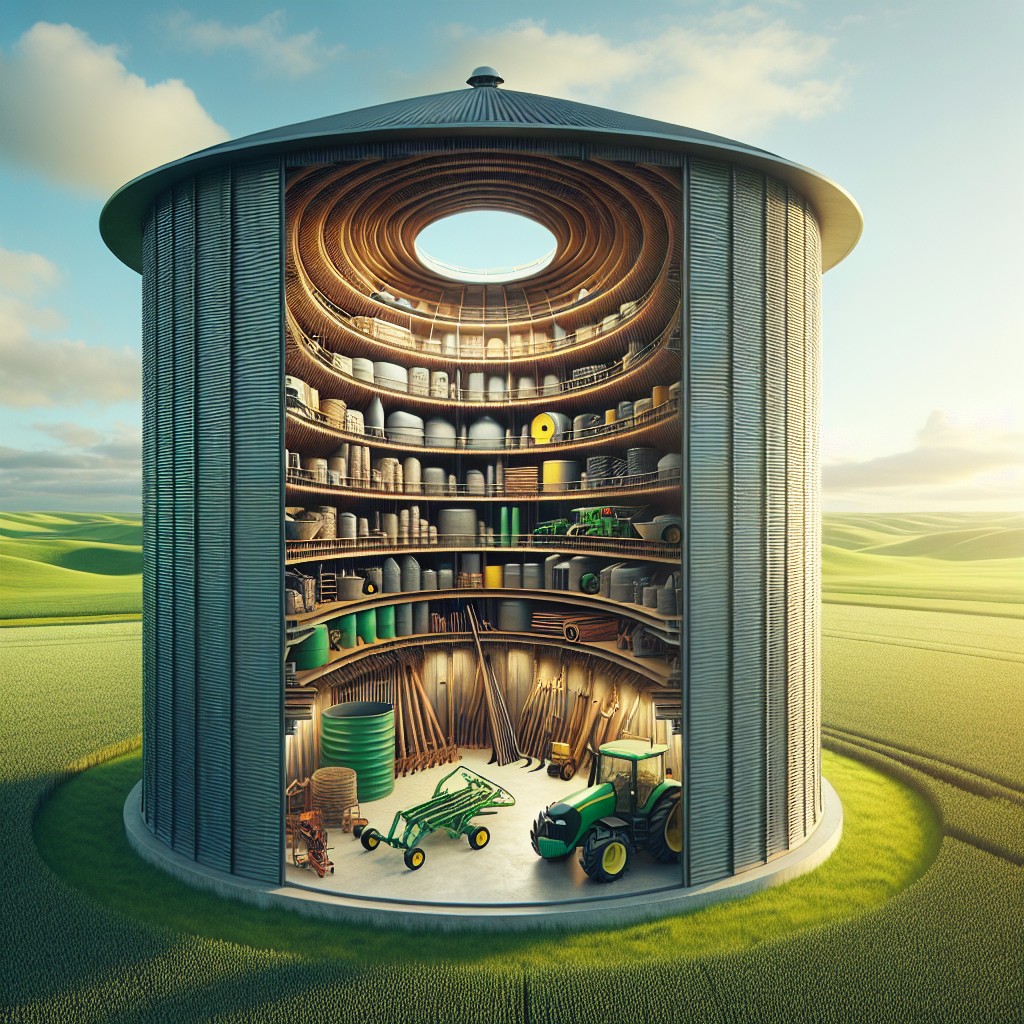

Utilizing Vertical Space in Grain Bin Sheds

Maximizing the use of available height not only increases storage capacity but also enhances operational efficiency. Here are some impactful ways to leverage vertical space:

- Install tiered shelving to organize smaller items, keeping them accessible while freeing up floor space.

- Consider tall, slender storage units that align with the curved walls, making the most of the unique shape of the grain bin.

- Employ stackable bins or totes which can be reconfigured as needed, providing flexibility in storage arrangements.

- Utilize overhead hoists or pulley systems for easy lifting and maneuvering of goods, reducing the need for extensive floor space.

- Integrate lofted areas for additional storage or office space, capitalizing on the height without impeding the functionality below.

- Incorporate drop-down workstations from the ceiling that can be stowed away when not in use, keeping the work area clutter-free.

By thoughtfully planning the vertical space, grain bin sheds not only store more effectively but also operate with greater ease.

Multipurpose Grain Bin Sheds

Multipurpose grain bin sheds embody versatility, serving various functions beyond mere storage. Ideal for those looking to maximize utility, these structures can double as workshops, garages, or even recreational spaces.

Opt for removable partitions to easily reconfigure the interior according to current needs. Including skylights or solar panels transforms these sheds into energy-efficient hubs. Moreover, integrating lofted areas can offer extra space for an office or a cozy retreat, enhancing the shed’s functionality without expanding its footprint.

By considering the integration of plumbing and electrical systems during the design phase, your shed can seamlessly transition between roles while keeping adaptation costs minimal.

Retractable Grain Bin Shed Roofs

Retractable roofs on grain bin sheds offer a versatile solution to varying weather conditions and operational needs. Here are a few key points about this innovative feature:

- Enhanced Accessibility: Retractable roofs make it easier to move equipment in and out without height restrictions, streamlining maintenance and loading tasks.

- Weather Adaptability: With the ability to close the roof during inclement weather, precious grain is protected from moisture and other elements that could otherwise lead to spoilage or damage.

- Natural Ventilation: Opening the roof in favorable weather conditions allows for natural air circulation, which can help regulate the temperature and moisture levels within the bin, preserving the quality of the grain.

- Operational Efficiency: Thanks to the convenience of a retractable roof, the need for manual opening and closing of traditional roof accesses is reduced, saving time and reducing labor costs.

- Customizable Control Systems: These roofs can be fitted with manual or automated control systems to suit different farm sizes and technological preferences, from simple hand-operated mechanisms to sophisticated remote-controlled systems.

By integrating a retractable roof into a grain bin shed, storage facilities become more functional while improving the overall management of grain reserves.

Interactive Grain Bin Shed Designs

Incorporating interactive features into a grain bin shed can significantly enhance functionality and user experience. Consider touch-screen control panels or apps that allow you to monitor storage conditions or manage inventory levels remotely. Such technology can offer real-time data on temperature and humidity, essential for preserving grain quality.

Another interactive aspect could be automated loading systems that streamline the process of moving grain to and from the shed. Sensors can help detect when bins reach certain fill levels, prompting automated conveyors to engage and prevent overfilling or spills.

For educational or visitor-friendly operations, interactive displays can be installed to explain the processes within the shed, offering insights into agricultural practices and the journey of grain from farm to table.

By integrating these interactive elements, you not only boost the shed’s efficiency but also foster a connection between technology and agriculture, paving the way for more informed and technologically savvy farming practices.

Grain Bin Sheds With Integrated Technology

Innovations in technology have propelled grain storage into the modern era, allowing for a smarter and more efficient management system in grain bin sheds. Integrated technology transforms ordinary silos into technologically savvy spaces, benefitting both large-scale operations and family-owned farms.

Automated Monitoring Systems: Sensors placed inside the bin relay real-time data on grain temperature and moisture levels, ensuring optimal storage conditions and preventing spoilage.

Inventory Management Tools: Software connected to your storage system allows for tracking grain quantities, simplifying management and forecasting for future yields.

Climate Control Features: Advanced systems regulate the internal climate, automatically adjusting to variances in external temperature to maintain consistency within.

Remote Access Controls: Through mobile apps, farmers can effortlessly control and monitor their grain bins from anywhere, providing convenience and flexibility.

Smart Loading and Unloading: Automated conveyor systems powered by smart technology enhance the efficiency of moving grain to and from storage, saving time and reducing labor costs.

Embracing these cutting-edge tools not only improves the longevity and quality of stored grains but also streamlines operations, carving a path toward a more sustainable and profitable agricultural practice.

Cost-efficient Grain Bin Shed Ideas

Creating a grain bin shed within a budget doesn’t mean sacrificing quality. Here are some strategies to achieve cost-efficiency:

- Repurpose Materials: Seek out used grain bins from farms that are upgrading or dismantling their facilities. Not only does this approach recycle materials that might otherwise be discarded, but it can also significantly reduce your costs.

- Simplify Design: Opt for a basic, no-frills structure. Reducing complexity minimizes labor and material expenses.

- DIY Construction: If you have the skills, consider self-building the shed. Following clear plans and safety guidelines, constructing the shed yourself can save on labor costs.

- Local Sourcing: Purchase materials from local suppliers to eliminate high shipping fees.

- Group Purchases: If multiple sheds are required, or if neighbors also need materials, buy in bulk to leverage discounts.

- Government Subsidies: Check for agricultural grants or tax incentives for building grain storage that may offset initial costs.

By focusing on these points, you can achieve a functional and economically sound grain bin shed.

Secured Grain Bin Sheds for Weather Protection

Securing your grain bin shed against harsh weather conditions extends its longevity and safeguards your inventory. Here are critical points to ensure your structure can withstand the elements:

- Reinforced Structures: Employ weather-resistant materials such as galvanized steel, which stands up to high winds and corrosion. Reinforce the roof and wall connections for added stability.

Waterproofing: Apply sealants and waterproof coatings to prevent moisture ingress, which can spoil grain and lead to mold issues. Consider also the slope of your land and position your shed to avoid water pooling.

Windproofing: Install heavy-duty door latches and strengthen the anchoring system of your grain bin shed to prevent damage caused by gusts and storms.

Insulation: High-quality insulation not only maintains temperature but also can offer additional structural support against heavy snow or ice accumulation on the roof.

Heat-shielding: In areas with high temperatures, reflective coatings can prevent the grain bin from absorbing too much heat, which could lead to spoilage or pests.

By anticipating weather threats and using appropriate materials and designs, you can create a secure environment that keeps your grain safe in virtually any conditions.

Portable Grain Bin Sheds

For farmers and agricultural professionals who require the flexibility to adapt to changing needs and locations, portable designs offer an ingenious solution. These structures typically come with features such as skid-mounted frames and reinforced corners for durability during transport. Their modular nature allows them to be disassembled, moved, and reassembled with minimal effort—a boon for operations that are leasing land, undergoing rotational grazing, or those who frequently move storage to different sites.

The use of lightweight materials contributes to ease of movement without sacrificing structural integrity. Some models include integrated wheels and hitch systems that enable them to be towed by standard farm vehicles. It’s also not uncommon for these sheds to feature pre-wired electrical systems that can be quickly connected to a power source, ensuring that the transition from one location to another is as smooth as possible.

Opting for a portable shed can also provide financial savings when it comes to land use and preparation. Since they do not require permanent foundations, these structures can reduce the need for extensive ground works, which can be both costly and time-consuming. It’s a practical approach that aligns with the dynamic nature of modern agriculture, where speed, efficiency, and adaptability are key to success.

Grain Bin Shed Renovation Strategies

Renovating existing grain bin sheds can breathe new life into aging structures and enhance their functionality. Here’s how:

- Assess the Integrity: Begin with a thorough inspection of the shed’s frame, panels, and foundation for any corrosion or damage. Address these issues promptly to ensure a successful renovation.

- Upgrade Insulation: Consider retrofitting with spray foam or panel insulation to maintain a consistent temperature and protect grain from moisture.

- Embrace Automation: Installing automated systems for temperature and humidity control can increase efficiency and reduce the risk of spoilage.

- Repurpose Surfaces: Paint or apply reflective coatings to the exterior to reduce heat absorption, and consider adding murals or signage for a visual refresh.

- Enhance Accessibility: Incorporate new, larger doors or conveyance equipment to improve access and ease the movement of grain in and out of the shed.

- Install Safety Features: Safety should be a priority; add railings, non-slip flooring, and emergency exits to comply with regulations and ensure operator safety.

- Opt for Energy Efficiency: If lighting or climate control systems are old, switch to energy-efficient alternatives like LED lighting and solar-powered fans to cut operational costs.

- Maximize Space: Introduce smart shelving or gravity-fed dispensing systems to make the most of the space available and streamline operations.

With these strategies, you can effectively give an old grain bin shed a new lease on life while ensuring it meets current and future operational needs.

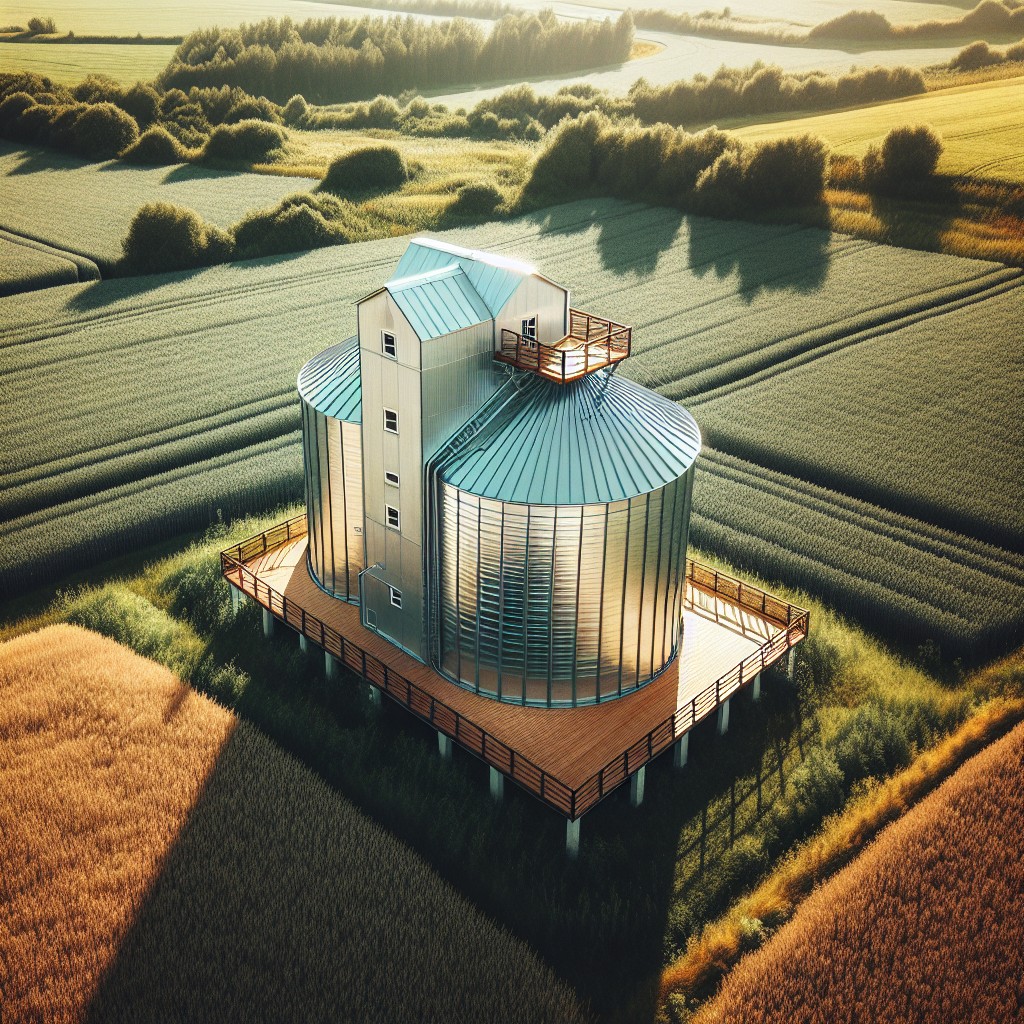

Grain Bin Sheds With Viewing Decks

Integrating viewing decks into grain bin sheds offers both aesthetic and functional benefits. Elevated platforms allow for a panoramic perspective of your property, as well as close monitoring of operations without disrupting the workflow. They can serve as a space for relaxation, making them a desirable addition for farm owners who enjoy watching sunsets or keeping an eye on the fields.

- Elevated space utilization: The deck transforms the roof into a usable area, offering a vantage point and potential for observations of the surroundings.

- Surveillance advantage: Having higher ground helps in overseeing grain loading and unloading processes, monitoring the condition of crops or the effectiveness of farm workers.

- Recreational benefits: Viewing decks provide a serene spot for breaks during a long day, potentially increasing overall satisfaction and reducing stress levels on the farm.

- Property value addition: A shed with a unique feature like a viewing deck can enhance the overall value of the property.

- Personalized touch: Decks can be customized to fit individual style and needs, including railings, seating arrangements, and even small garden spaces for a touch of greenery.

Insulated Grain Bin Sheds for Temperature Control

Controlling the temperature within a grain bin shed is crucial to maintaining the quality of the stored grain. Insulation is one of the most effective methods to achieve this:

– Materials Matter: Select high-grade insulation materials like spray foam or rigid boards that adhere well to the metal structure while offering superior R-values. – Seal the Deal: Ensure that all joints and seams are well-sealed to prevent thermal bridges that can cause heat and cold infiltration, affecting the internal climate. – Reflective Coatings: Consider reflective barriers, which can be applied to the exterior of the bin to deflect sunlight and reduce heat absorption in warmer climates. – Ventilation Integration: Combine insulation with a well-designed ventilation system to manage moisture and prevent condensation, which can spoil the grain. – Environmental Impact: Opt for eco-friendly, low-VOC insulation options that contribute to a healthier environment both inside and outside the shed. – Installation Accuracy: Employ professional services for installation to ensure that the insulation is properly fitted, maximizing its effectiveness.Note that the right insulation not only prevents spoilage but also saves energy, leading to lower utility bills and an overall more sustainable operation.

Grain Bin Sheds With Built-in Pest Control

Integrated pest management is a crucial aspect of grain storage, demanding a proactive approach to maintain grain quality. Innovative bin sheds now introduce features to deter pests through physical and chemical means.

Specialized wall coatings resist insects, while built-in airtight seals prevent rodent entry. Furthermore, advanced sheds are equipped with monitoring systems that alert farmers to early signs of infestation, enabling prompt action.

Automated temperature and humidity controls create an environment less hospitable to pests, safeguarding grain integrity. These built-in defenses streamline pest control without the heavy reliance on external pesticides, preserving both the grains and the surrounding ecosystem.

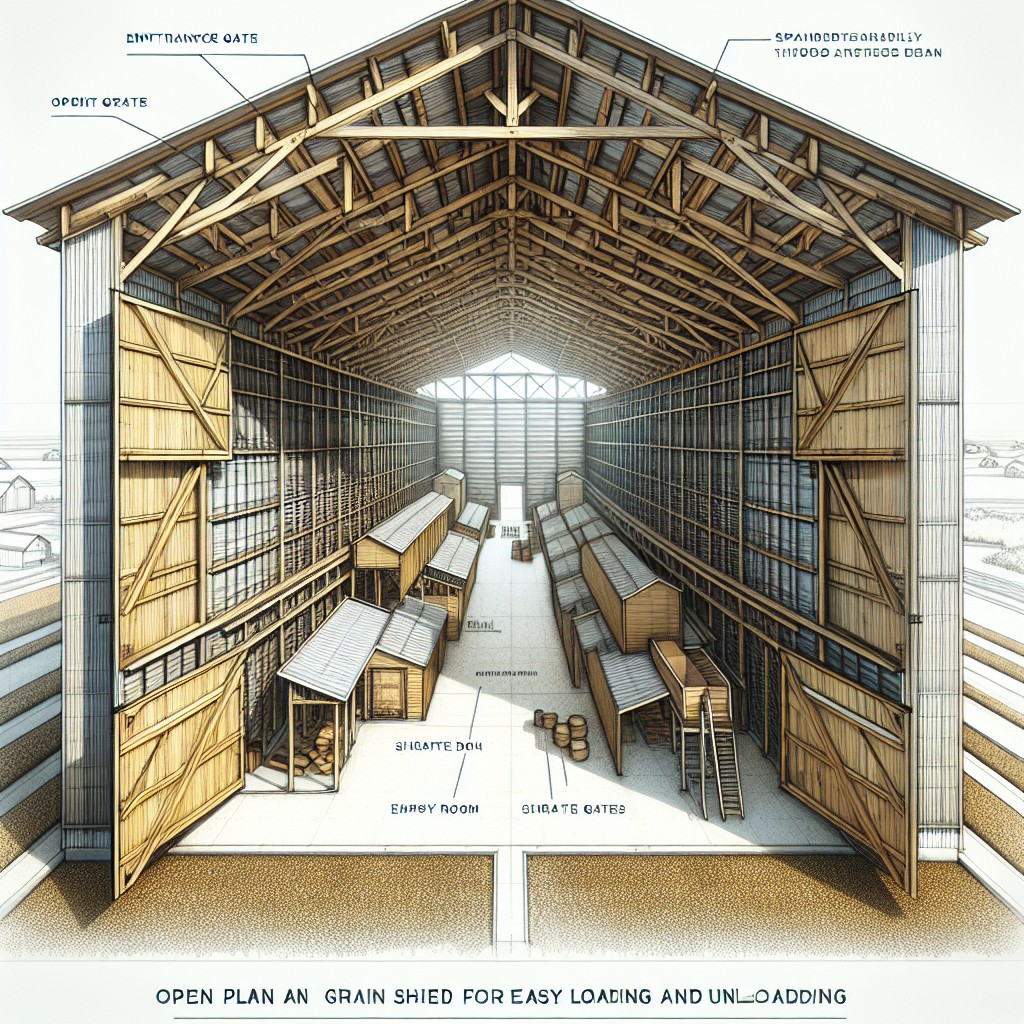

Grain Bin Shed Designs for Easy Loading and Unloading

Maximizing efficiency during the loading and unloading process in grain bin sheds is crucial for operational flow. To achieve this, consider the following points:

- Install large, sliding door systems that can accommodate machinery like forklifts and tractors, ensuring seamless movement of goods in and out of the shed.

- Implement drive-through bays which allow trucks to enter from one side and exit from the opposite, reducing turnaround times.

- Elevate the floor level of the shed or construct a raised unloading platform to align with the truck beds, facilitating gravity-assisted unloading and minimizing the need for additional equipment.

- Incorporate advanced conveyor belt systems that can swiftly move large volumes of grain with minimal manual handling.

- Design the shed layout, ensuring an unobstructed path to the storage area with ample space for vehicles to maneuver.

- Integrate smart storage solutions, like retractable walls or adjustable partitions, to customize the storage area as per the loading requirements, allowing for flexibility and adaptability.

- Consider the placement of windows and skylights strategically to improve visibility during daytime operations, thus making the loading and unloading process safer and more efficient.

By addressing these design elements, the flow of goods is optimized, saving time and reducing the risk of product damage or loss during handling.

Maximum Storage Grain Bin Sheds

Maximizing the utility of grain bin sheds hinges on a few key considerations, each contributing to the overall efficiency and capacity of the structure:

- Smart Design: Implement shelves and compartments within to make use of every cubic foot. Consider the golden ratio of horizontal to vertical space when planning the interior to balance accessibility with volume.

- Material Handling Systems: Incorporate conveyor belts or augers, which facilitate easy movement of grain within the shed, thereby reducing the storage footprint and increasing efficiency.

- Bulkheads: Use movable bulkheads to compartmentalize grains, optimizing space based on seasonal storage needs without investing in more infrastructure.

- Stackability: Choose containers and totes that are stackable, ensuring the weight is evenly distributed and the height of the space is fully utilized.

- Aeration Systems: Integrate aeration systems that enable deeper grain storage while maintaining quality, eliminating the need for frequent rotation and preserving the maximum quantity of grain.

- Modular Elements: Utilize modular storage units that can be expanded or contracted based on the current storage volume required, facilitating peak season demand without wasting space in slower periods.

By concentrating on these points, you significantly enhance storage capacities, ensuring that every inch of your grain bin shed is used effectively.

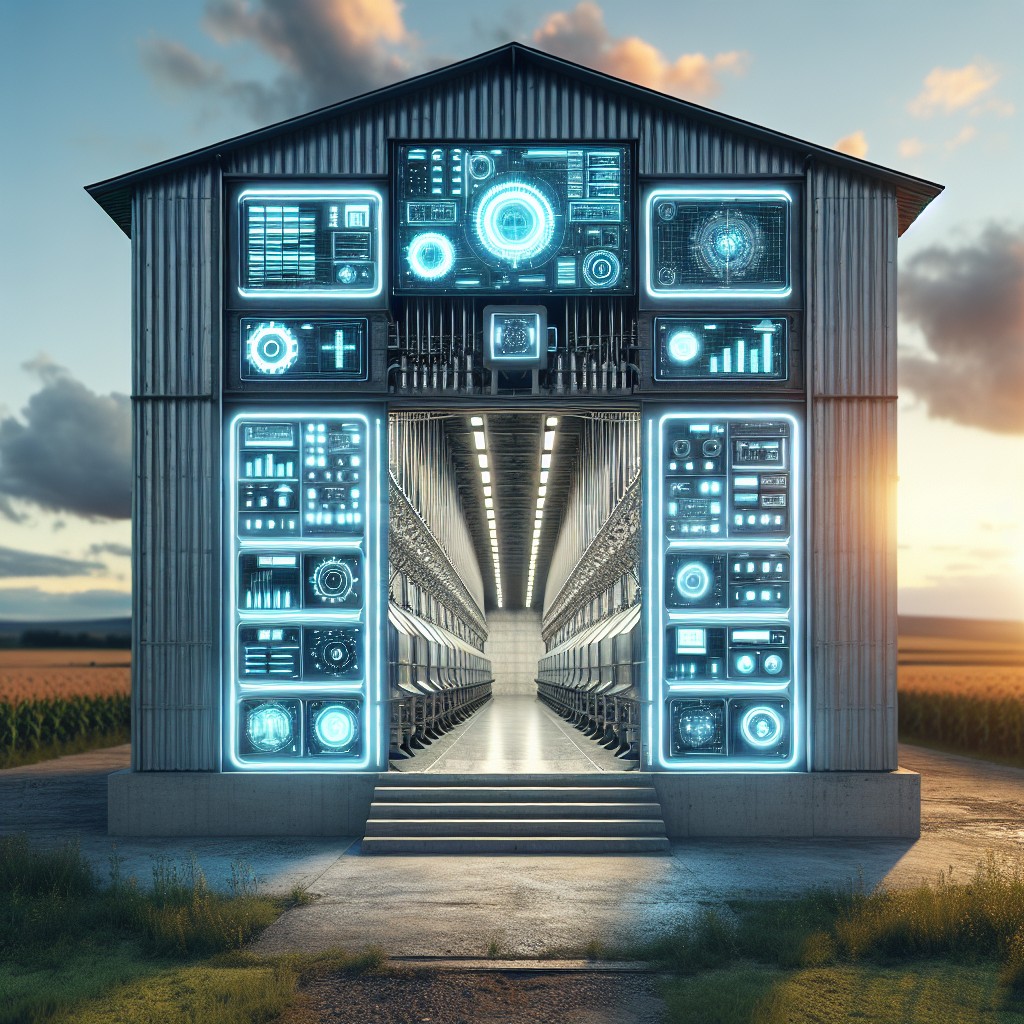

Grain Bin Sheds With Futuristic Controls

Incorporating advanced technology into your grain bin shed elevates its functionality to new levels of efficiency and ease of use. Smart systems can now be integrated to monitor grain conditions in real time, adjusting temperature and humidity through automated controls to preserve quality.

Remote management apps allow you to adjust settings and receive alerts from anywhere, ensuring your grain remains in the best possible state even when you’re off-site. Automation can extend to loading and unloading mechanisms, reducing the need for manual labor and streamlining the process.

Additionally, incorporating renewable energy sources, such as solar panels, can power these futuristic controls, enhancing the sustainability of the storage system. With these tech-savvy upgrades, the modern grain bin shed becomes more than just a storage space—it transforms into a cutting-edge asset for any agricultural operation.

Optimizing Air-flow in Grain Bin Sheds

Maintaining optimal air-flow in grain bin sheds is crucial to prevent moisture accumulation, which can lead to mold growth and spoilage. Here are several strategies to enhance ventilation:

- Install strategically placed vents at the roof and base to facilitate natural convection currents. Warm, moist air rises and exits through the top, drawing in cooler, drier air from the bottom.

- Employ aeration fans to regulate air movement, especially critical in areas with minimal natural airflow. This active system can be adjusted based on humidity levels and temperature.

- Consider louvered wall panels, which can be opened or closed to control airflow according to the external weather conditions.

- Ensure the shed is well-sealed to prevent the entry of rainwater but not so tight as to restrict air exchange.

- Use perforated flooring systems that support grain while allowing air to move upward evenly, preventing “dead zones” with little air movement.

- Regularly monitor and adjust airflow based on the stored grain’s condition and outside weather patterns, using sensors and automated systems for precision.

Luxury Grain Bin Shed Designs

Transforming a functional space into a luxurious focal point, upscale grain bin sheds cater to those who seek elegance and comfort alongside utility. These designs often feature high-end materials such as tempered glass walls for natural lighting and a sleek industrial feel. Inside, ambient LED lighting systems can be installed to highlight architectural features and provide efficient task lighting.

Customization plays a significant role in these lavish structures, with tailored shelving and storage solutions that maximize space while maintaining a high-end aesthetic. Climate control is also paramount, with state-of-the-art insulation and temperature regulation systems ensuring grain integrity.

For added opulence, specially designed lounging areas can be integrated, offering a space to relax or entertain within the same structure. These zones might feature plush seating, entertainment systems, and even mini-bars, elevating the traditional storage shed to a stylish retreat.

Advanced security systems, including biometric access and surveillance, safeguard the valuable contents while providing peace of mind. Both functional and indulgent, these luxury sheds prove that practicality does not have to come at the expense of style and comfort.

Ideas Elsewhere

- https://talk.newagtalk.com/forums/thread-view.asp

- https://www.garagejournal.com/forum/threads/grain-bin-for-a-small-shop.186648/

- https://talk.newagtalk.com/forums/thread-view.asp

- https://www.farmshow.com/view_articles.php

Table of Contents

![How to Sell Leftover Building Materials? [Solved]](https://buildgreennh.com/wp-content/uploads/2022/07/sell-leftover-building-materials.jpg)