Last updated on

UK households and businesses use staggering amounts of plastic. An estimated 200 billion pieces of plastic, amounting to 5 million metric tons, change hands yearly. Fortunately, roughly half of that skips landfills and is recycled and repurposed, lowering the already detrimental environmental impact our reliance on plastic has.

The good news is that new production methods not only provide alternatives to traditional materials like glass, wood and metal but also offer opportunities for innovative products. Plastic sheets fall squarely into this category.

What Is a Plastic Sheet?

Most plastic waste comes from packaging, usually in the form of film. This is very thin (under 0.2mm). Plastic sheet differs in that it is thicker, stiffer, more durable and can be shaped and formed to standard building sizes, opening a range of possible uses.

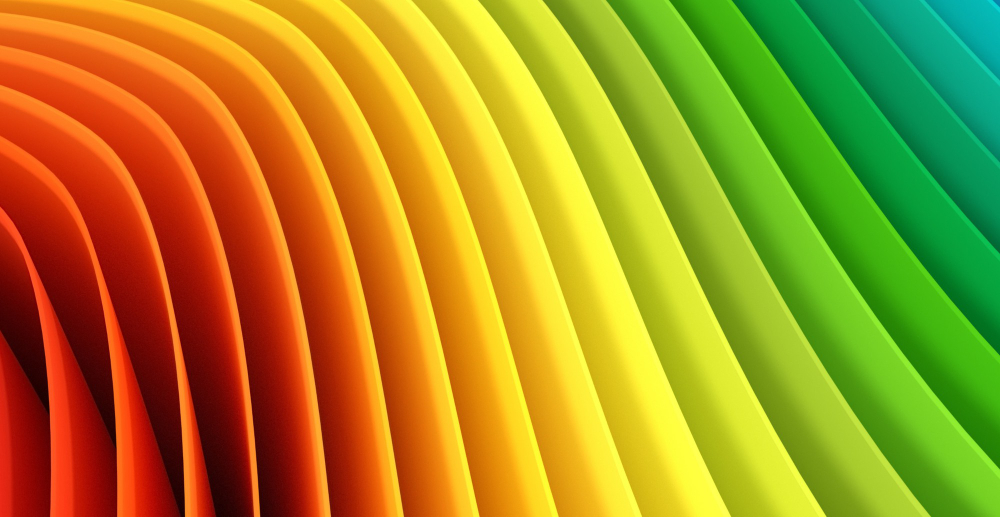

Besides being made from a variety of raw or recycled materials and tailoring needs with varying properties, sheets can additionally be modified for appearance in terms of surface finishes, textures, designs and colours.

How It’s Made

Sheeting can be made from raw or recycled thermoplastics, usually in the form of pellets. These can be heated, processed and repurposed without affecting their chemical or physical properties. This is one reason for the high uptake of plastic recycled sheets in numerous industries.

The production process is generally uniform across all thermoplastics and involves melting and heating pellets until they’re liquefied and then pushing the molten mixture through casting dies or moulds in a specified shape and form. The materials are left to cool and harden, then removed from the moulds. The final product is then cut, shaped and worked to meet specific needs.

Where It’s Used

There are hundreds of industries and applications of recycled sheets:

- Construction – sheeting finds its use in hoardings, carports, pergolas, temporary storage buildings, concrete formwork, portable toilets, fences, skylights, greenhouses and kitchen countertops, among other items.

- Signage – the plastic sheet is printable, so it works well in signage, retail displays, advertising boards, partitions, and shelving.

- Electronics – non-conductive thermoplastic sheets are used in computer screens, electronic housings and covers, switches and more.

- Automotive and aerospace industries – boot liners, fenders, dashboards, door trim, interior wall panels, seating components, food trays and other products are just a few ways plastic sheets are used in cars, lorries and aeroplanes.

- Military and law enforcement – high-impact-resistant, transparent and lightweight thermoplastic sheet is the main ingredient in items like bulletproof vests, shields and windscreens.

- Sporting and recreational gear – favourable properties make sheeting useful in kayaks, ATVs, sleds, RC cars, and playground and exercise equipment.

- Manufacturing and warehousing – conveyor systems parts, containers, spill pallets, boxes and numerous packaging materials consist of either raw or recycled plastic sheets.

These are just a few of the uses that make the material so sought after. By using one or a combination of thermoplastics, and modifying properties with the use of additives, the applications for sheets and the possibilities they provide are virtually endless.

Benefits Plastic Sheeting Provides

There are dozens of reasons to consider plastic sheeting, and in particular, plastic recycled sheets. They can be flexible and pliable, or extremely strong and rigid.

Their properties can be changed according to need and using several production methods, besides extrusion, described above. All are durable, can be used in a variety of settings, both in and outdoors, and are easy and quick to manufacture in high volumes and consistent sizes.

In addition, colours, opacity, textures and sheen can all be tailored to meet customer needs. Recycled sheets also reduce waste and carbon footprints, and can be further repurposed with relatively low production and processing costs.

Easy to Fabricate and Machine

Many thermoplastics are used in the production of sheets; all have varying melting points, but they can all be thermoformed, which broadens the applications for which they can be used. In addition, the completed sheets can be shaped and sized to any desired size or shape with simple hand tools like saws and routers; most can be drilled and joined, as well as machined for smoother surfaces and edges.

Strength and Durability

While the mechanical properties of sheets depend on the raw materials used in their production, sheets display a high level of impact and abrasion resistance, perform exceptionally well against chemicals, liquids and UV radiation won’t rot or decay and will last for decades. They also work well when exposed to heat and with additives hold their own in fires. Many are used as cost-effective and durable substitutes for metals, glass and wood.

Lightweight

One area where sheets outperform traditional materials is weight; popular types such as acrylic sheets weigh half as much as glass but are much stronger, and more resilient to breakage. All plastic sheets are significantly lighter than the materials they have replaced.

Variety of Finishes

Additives like pigments and colourants are added to obtain the desired colours. UV stabilisers prevent fading and staining, and carbon and glass add surface and core strength. There is also the choice of transparent, opaque or translucent sheets in areas like retail displays and signage. Surfaces can also be matte or gloss, and smooth or rough.

Eco-friendly and Recyclable

Sheets made of a single thermoplastic, like that found in most consumer-grade products, are the easiest to recycle. Industrial and engineered sheets combining several materials or additives may need more work but are also recyclable. This involves melting the sheet, processing and forming.

The benefits are that even older sheets retain their characteristics, but can be formed into entirely new products. Recycling not only reduces environmental impact but makes materials and repurposed items cheaper to make and buy. For businesses heavily relying on plastic, there are substantial savings.

Common Thermoplastics and Trade Names

There are scores of sheet varieties, but the most common are acrylics, polycarbonate, PVC, ABS, polyethylene, and polypropylene. Some have been around longer than others and are also known by their trade names.

Acrylic sheet, or Perspex/Plexiglas is a lightweight, durable and scratch-resistant alternative to glass found in windows, car light covers, helmet visors, store displays and shelving. It is easy to work and can be had in a transparent or frosted finish.

Kydex, or ABS plastic sheet is very rigid, tough and naturally UV and scratch, making it ideal for industrial and engineered products and applications. High-density polyethylene, or HDPE, is another industrial-grade sheet with exceptional water, weathering and impact resistance, commonly found in pipes and plumbing products, as well as decking, signage and various marine uses like boat doors and hatches.

Polycarbonate sheets (Lexna, Makrolon, or Palsun) are another glass alternative boasting high chemical, impact and heat resistance and are seen in machine guards, security screens, greenhouses and more. Rigid foam PVC or Vekaplan is a lightweight and durable solution for shop fittings, displays and cladding.

The list can be populated with many more options, but the important thing to know is that plastic sheeting is available with the properties that work best in the intended setting and application, is offered in a range of finishes, is cheap and easy to produce and machine, and possibly most importantly can be recycled at any point without incurring unwanted waste.

Table of Contents