Last updated on

Industrial heating solutions are a critical component in various industries, providing the necessary heat for manufacturing processes, food processing, and chemical production. In today’s competitive landscape, optimizing efficiency and minimizing costs are essential.

In this blog post, we will explore the key aspects of industrial heating solutions, discuss ways to optimize efficiency, highlight successful case studies, address challenges, and take a glimpse into future trends.

Understanding Industrial Heating Solutions

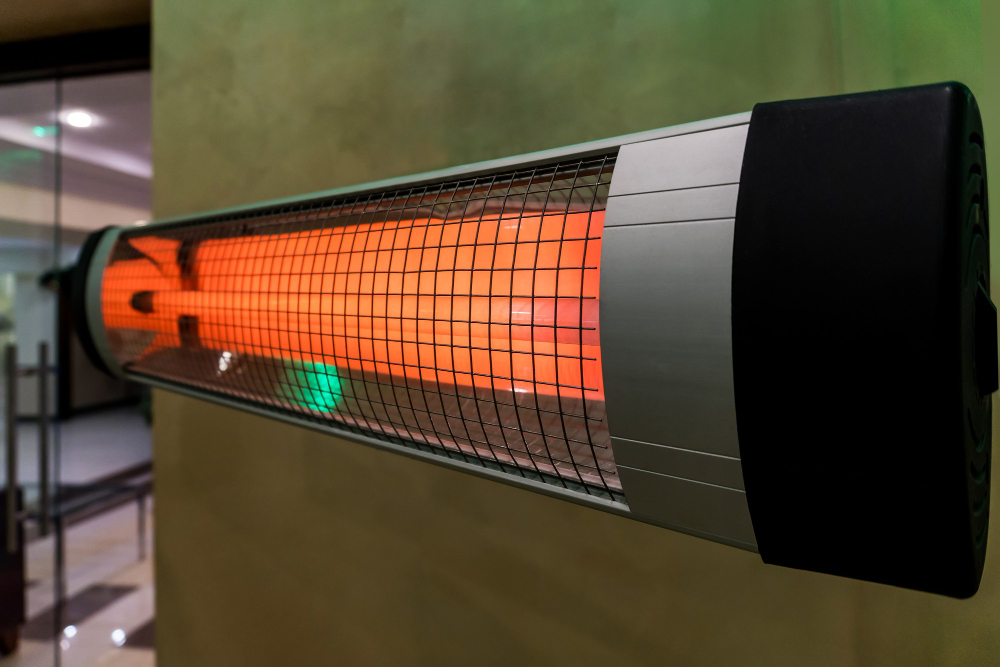

To begin, it is important to understand the different types of industrial heating systems available. Convection heaters, radiant heaters, and induction heaters are commonly used to meet specific industry requirements.

Convection heaters blow hot air through space, radiant heaters emit infrared radiation to heat objects directly, and induction heaters generate heat within conductive materials using electromagnetic fields.

Choosing the Right Heating Solution

When selecting an industrial heating solution, several factors should be considered. Heat output requirements, energy efficiency, and safety features play a significant role in making the right decision.

Also, cold-weather roofing is a vital complement to industrial heating solutions, as it helps prevent heat loss during cold climates. Thus, it is essential to consider various factors such as energy efficiency, performance, and cost-effectiveness. Utilizing a cold-weather roofing calculator helps estimate the cooling and heating savings for flat roofs with non-black surfaces.

It provides valuable insights into the potential benefits of different roofing materials and their impact on energy consumption. By accurately assessing the heating needs of a facility, businesses can avoid overspending on excessive heating capacity or compromising on performance due to underpowered systems.

Optimizing Efficiency in Industrial Heating

Efficiency is crucial in industrial heating to reduce operational costs and minimize environmental impact. Proper insulation techniques can prevent heat loss and ensure that the generated heat is efficiently utilized.

Advanced control systems offer precise temperature regulation, allowing industries to maintain optimal conditions while avoiding energy waste. Additionally, incorporating waste heat recovery systems can repurpose excess heat generated during industrial processes, further enhancing overall efficiency.

Successful Case Studies

Several industries have successfully implemented industrial heating solutions to improve their operations. In the manufacturing sector, efficient heating systems have helped streamline production processes by providing consistent and controlled temperatures for various applications such as drying, curing, and molding.

The food processing industry relies heavily on heating solutions to ensure food safety, quality, and compliance with regulatory standards. Similarly, the chemical and pharmaceutical industries utilize advanced heating technologies to facilitate precise reactions and maintain stringent temperature control.

Challenges in Industrial Heating

While industrial heating solutions offer numerous benefits, they also come with challenges. Managing heating system maintenance and repairs is crucial to ensure uninterrupted operations. Regular inspections, cleaning, and servicing can help identify potential issues and prevent costly breakdowns.

Safety concerns in hazardous environments must be addressed through the installation of appropriate safety features and adherence to industry-specific regulations. Moreover, industries must stay updated with evolving regulations and environmental standards to align their heating practices with sustainability goals.

Future Trends in Industrial Heating

Looking ahead, future trends in industrial heating solutions are driven by technological advancements. Integration of the Internet of Things (IoT) and AI technologies allows for smart heating systems that can automatically adjust settings based on real-time data, optimize energy consumption, and provide predictive maintenance alerts.

The adoption of greener and sustainable heating solutions, such as solar thermal or biomass technologies, is gaining momentum as businesses strive to reduce their carbon footprint. Furthermore, advancements in heat recovery technologies enable industries to capture and reuse waste heat more efficiently, reducing energy consumption and costs.

The Takeaway

Efficient industrial heating solutions are essential for various industries to optimize performance, reduce costs, and meet regulatory requirements. By understanding different heating systems, considering key factors, and implementing strategies to enhance efficiency, businesses can navigate the complex landscape of industrial heating successfully.

Case studies highlight the positive impact of well-designed heating solutions across manufacturing, food processing, and chemical industries.

However, it is crucial to address challenges related to maintenance, safety, and compliance. Embracing future trends such as IoT integration, sustainable heating options, and heat recovery technologies will further unlock the potential of industrial heating, leading to a more sustainable and productive future.

Related reading:

Table of Contents